The escalating erosion of riverbanks and coastlines in Vietnam, driven by the impacts of climate change, is posing significant challenges to infrastructure development and construction activities. As a pioneering contractor in Vietnam, FECON, in collaboration with Raito Kogyo Group (Japan), has introduced the innovative RAS Column technology, a breakthrough solution that addresses most of the challenges previously encountered in riverine and coastal projects.

Introducing cutting-edge Japanese geotechnical technology to Vietnam

On December 14–15, the 5th International Geotechnical Conference (GEOTEC HANOI 2023) was held in Hanoi, attracting over 1,000 delegates from 40 countries, including many of the world’s leading scientists.

The conference featured six key thematic areas, each addressing some of the most pressing issues in today’s geotechnical and infrastructure development sectors: deep foundations, tunneling and underground space, ground improvement, geotechnical modelling and monitoring, landslides and erosion, offshore wind power, and coastal geotechnics.

In the session dedicated to landslides and erosion, an urgent global issue, more than 40 scientific presentations were delivered by international experts. Notably, the RAS technology, a pioneering Japanese geotechnical innovation introduced by FECON in partnership with Raito Kogyo, garnered significant interest from researchers and contractors alike. The technology was showcased at the central exhibition booth.

Mr. Pham Viet Khoa, Chairman of FECON Group and Head of the GEOTEC HANOI 2023 Organizing Committee emphsized that as an island nation, Japan places high amphsis on addressing coastal erosion and has developed many advanced solutions. Over the past five years, the RAS technology, developed by Raito Kogyo, has been widely applied in Japan. This technological solution enhances foundation-bearing capacity and provides robust stabilization for coastal structures.

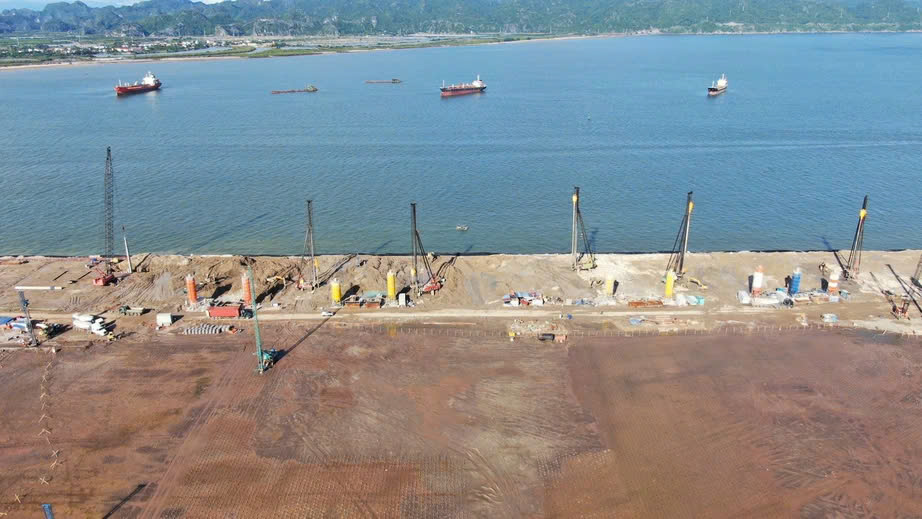

Mr. Khoa further noted that FECON first explored this technology following GEOTEC HANOI 2019. After successful technology transfer, FECON implemented this technology in the construction of Berths 5 and 6, Lach Huyen Port, Hai Phong.

The deployment proved highly effective, demonstrating exceptional load-bearing capacity and uniform quality across all 1,000 large-diameter (up to 1.8 meters) and deep (up to 30 meters) columns. Most significantly, the ground treatment phase of the project was shortened by approximately one year compared to conventional methods.

“For years, any solutions have been proposed, yet none have fully addressed the dual challenge of improving ground bearing capacity while effectively preventing riverbank and coastal slope failures. RAS technology has proven to be a near-comprehensive solution for these challenges in port or industrial plant projects located in erosion prone areas. It provides exceptional resistance against erosive forces that have long troubled our engineering community” Mr. Khoa concluded.

According to Mr. Nguyen Dinh Cuong, Head of the Ground Improvement Division, Technical Department at FECON, the application of RAS technology in cement-treated soil column construction meets quality requirements while consuming less cement compared to traditional Cement Deep Mixing (CDM) techniques. The primary objective of adopting the RAS Column technique is to enhance construction productivity, thereby substantially reducing both project timelines and overall construction costs.

Versatile Applications Across Various Project Types

Following its successful application at the Lach Huyen Port project, FECON representatives stated that RAS technology could be expanded to other projects nationwide due to its technical and economic advantages.

Moreover, drawing from implementation experience in both Japan and Vietnam, FECON conducts soil investigations for each specific project to determine the appropriate mix design for soil-cement columns. This tailored approach provides a solid foundation for expanding the technology’s use beyond riverbank and coastal protection projects to a wide range of applications with varying structural load requirements.

RAS technology employs a counter-rotating blade and mixing head driven by a dual-motor system, which enhances the mixing efficiency of cement slurry with in-situ soil, producing highly homogeneous cement-soil columns. The high-capacity dual motor can penetrate stiff clay layers, forming cement-soil columns up to 2.5 meters in diameter and 35 meters deep. The continuous flight auger aids in reverse mud circulation, minimizing disruption to adjacent structures.

The construction parameters are automatically controlled and monitored in real time via control cabin equipped with a specialized sensor system connected to dedicated computer software. Throughout the construction process, experienced engineers continuously oversee operations, enabling timely responses and highly efficient on-site adjustments.

Thanks to these advantages, the RAS technology not only improves construction quality but also offers substantial competitive benefits over traditional CDM (Cement Deep Mixing) techniques.

Experts have identified RAS technology as a breakthrough solution in the design and construction of load-bearing structures in riverbank and coastal areas, particularly for projects requiring both structural capacity and erosion resistance to ensure long-term sustainability.

This technology is especially meaningful for Vietnam, given its timely transfer and implementation amid increasingly severe riverbank and coastal erosion. With forecasts indicating continued challenges ahead, the solution is critically important for one of the five countries most vulnerable to climate change.